Good for the planet, nothing goes to waste, with Argan’s ‘No Loss, No Waste’ characteristics it ranks top in sustainability. Food loss is food lost during harvest, handling, and production. Food waste is food not consumed, lost in the retail and consumption phases. In this blog, we describe why culinary argan oil is so sustainable, and list some of the ‘by-products’ for new/novel products and applications.

A by-product is a ‘left-over, or waste’ product after production that can be used for something else: transforming waste materials into useful products or resources, either through direct use or by converting them into higher-value products.

1- Wasting like crazy

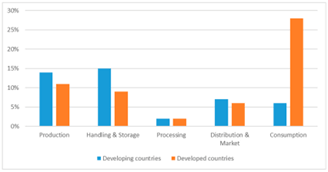

Food waste is food that is not eaten; not used or thrown out in the distribution, retail, and consumption phases. About a third of our food is not eaten, and 90% of it goes to a landfill. The FAO estimates that around 14 percent of food is lost during upstream production, and the UN Environment Program’s 2021 Food Waste Index Report estimates that a further 17 percent of food was wasted downstream in retail, food service, and households.

The US Environmental Protection Agency (EPA) reports food waste is the single most common material discarded at landfills, The impact on our environment is immense. And let’s not talk about food insecurity or its impact on our planet. Global costs of FLW (Food Loss Waste) may reach close to a trillion dollars ( 12 zeros) in a few years.

FLW accounts for more than 600 billion dollars in 2018 according to a July 2019 publication in Foods, an international peer-reviewed journal on food science. Just for reference, according to the World Trade Organization (WTO) in 2022 the value of the world merchandise trade was 25,3 trillion dollars.

Developing countries have more loss, developed countries have more waste according to the above-mentioned publication. Surprised ‘we, here’ waste 5 times more during consumption?

Culinary Argan Oil is a niche player in the field of vegetable oils

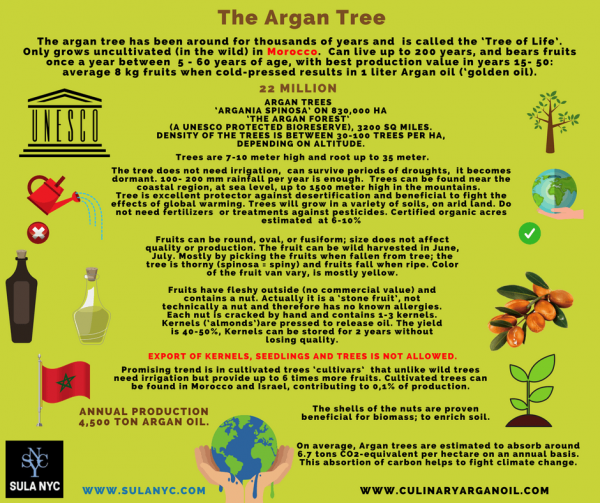

Culinary and Cosmetic Argan oil both come from the fruits of the argan tree.

This is such a wonderful tree, gives fruits, provides shade, and helps to fight desertification – all on its own; no help is needed. The volume of the Argan production mostly depends on mother nature; between June and August the fruits are wild harvested; reap what she gives. So, in the value chain from growth to production, waste doesn’t occur. No tree shaking, no irrigation, fertilizers, or pesticides: nothing.

The fruit self decides when it’s ripe for production by gracefully descending from the tree to the earth. Boink! That’s it. There are no Argan greenhouses, no Argan from a lab. Pure as pure can be. Vegan and Cruelty-free as well.

With such a good track record on TLW, Carbon footprint, and rural impact, isn’t it clear EVAO tops the ranks of most sustainable vegetable oils?

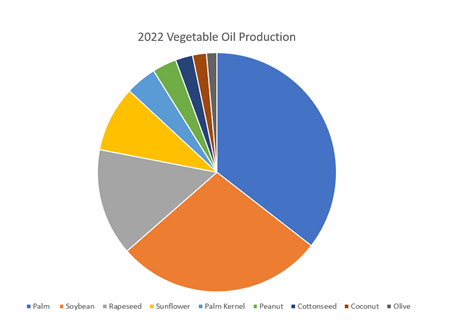

2- The production of vegetable oils increases

Worldwide about 220 million metric tons of vegetable oil were produced in 2022. More than two times as much as 20 years ago, when 90 million tons were produced. Most of the volume is used as cooking oil, with significant volumes for the cosmetic industry and as fuel. Here are the top 9 produced vegetable oils:

In the USA soybean oil is the most consumed, with 12 million metric tons in 2022. Argan oil production is way less than the 3 million metric tons of olive oil: it’s, therefore, a ‘no show’ in global statistics on vegetable oils. Such a ‘no show’ in reports happens to other much more known oils as well.

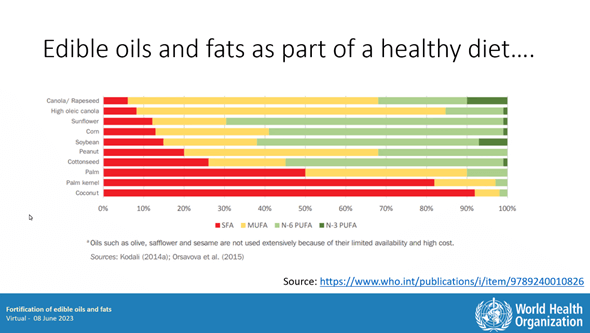

In June 2023, the WHO published “ Edible oils and fats as part of a healthy diet”. Ten oils listed and ranked (see below) in four Fatty Acids categories: Saturated Fatty Acids (SFA), Mono Unsaturated Fatty Acids (MUFA), and two Poly Unsaturated Fatty Acids (PUFA): Omega N-6, and Omega N-3.

Coconut oil, Palm oil, and Palm Kernel oil are the top 3 oils with the most SFA’s: unhealthy fatty acids. Canola oil and Rapeseed oil have the lowest SFA’s, less than 10%.

We were not surprised Argan oil (EVAO -Extra-Virgin Argan Oil), with ZERO SFA was not listed. But three other vegetable oils were not listed either: Olive, Sesame, and Safflower oil. Why? The footnote in the graph answers this question: ‘They are not used extensively because of their limited availability and high costs’.

Really? Limited availability? The last time we checked these oils were sold in every supermarket. A very helpful informative graph though. Talking about information, and education: we have our work cut out for us as Culinary Argan oil is not a staple on every shelf. Yet.

3- The extraction of seeds results in Oil, Loss, Waste, and By-Products.

This, for vegetable oils in general, is true. But not for Argan oil. As there is no loss or waste during the phases of growth, harvesting, and handling of Argan oil we feel it takes the lead in the ranking of vegetable oil on sustainability.

Most cooperatives have a machine to remove the soft flesh of the argan fruits resulting in:

- Pulp residue (or Argan Fruit Residue) and

- Argan nut (shells & kernels -‘almonds’).

A 2021 study on the production process lists: 43% pulp residue, 52.6% shells, and 2% APC as by-products, and mentions they are hardly being exploited at present. The pulp residue, rich in carbohydrates and fibers, is the least-valorized by-product; it is mainly (and traditionally) used as cattle feed.

Recently, due to its richness of carbohydrates, it is being researched for more valuable applications such as bioethanol. This applies to the shells as well. The research is promising, both products can have more value than ‘just’ cattle feed. To list a potential use of pulp residue: extract Polyhydroxy butyrate (PHB) a polymer belonging to the polyesters class of interest as bio-derived and biodegradable plastics.

A 2020 study showed a promising use in Phytotherapy (the user of plants, herbs to manage health conditions), due to phenolic, antioxidant, terpenes (highly aromatic compounds) properties.

Processing of the kernels has two steps:

First, using two stones the shells are cracked by hand by women, releasing the kernels. Tough manual repetitive labor, one shell at a time. ‘Grab, Crack, Repeat’. Done for centuries, providing income to the women living in small rural communities. The kernels go on their way to extraction, the shells, now in shambles, are used in various ways: enrichment of the soil, cattle feed, and quite recently as ‘biomass’ and ‘bio powder’ ingredient. Read more in our by-products paragraph below.

The second step is the extraction of the oil from the kernels by cold-pressing and filtering. Minimal processing is the hallmark of Argan oil. No water, heat, or chemicals are involved. The residue of the kernels after pressing is called ‘Argan Press Cake’ (APC). This is also used as cattle feed; animals find it yummy. It is nutritious with its proteins, fiber, and minerals. Scientists recently have discovered a variety of other uses and promising applications of this APC which we will also talk about in the by-products paragraph.

It’s a clean process: kernels in, oil out. APC to animals or as a by-product.

As you know, olive oil is Argan’s well-known big sister, with a big presence and appeal. The extraction of olive oil is different from Argan oil. The oil is extracted from the olive -the fruit-, not from the kernel as Argan does. Argan residue is called APC: for Olive oil, it is called Pomace. Pomace is the residual paste that remains after the initial extraction of extra-virgin and virgin olive oils. This paste still holds a significant amount of oil, which can be extracted further using methods such as solvent extraction or mechanical pressing. The resulting olive pomace oil is of a lower quality.

4- By-products of Vegetable Oils

Vegetable oil production generates various by-products, some of which have important uses and applications. They have nutritional value and are influenced by extraction methods, the type of oil used, and of course market demands and technological innovations. Some of the best-known by-products of vegetable oils:

- Glycerin, a by-product of almost all vegetable oil processing, is a key component in soap production. Argan oil is an exception among vegetable oils in that it does not typically involve the production of glycerin as a by-product during its extraction process. Glycerin is not extracted; no chemical reaction is triggered. Olive oil is another exception as extraction; glycerin isn’t a by-product, The extraction of olive oil is different than argan oil The oil is extracted from the olive -the fruit-, not from the kernel as Argan does. Argan residue is called APC; Olive oil calls it Pomace.

- Lecithin: Lecithin is a by-product that is often extracted from soybean oil. It is used as an emulsifier in food and industrial applications.

- Resins and Adhesives: Vegetable oil derivatives are used in the production of resins and adhesives.

- Ink and Lubricants: Vegetable oil-based inks and lubricants are considered environmentally friendly alternatives to petroleum-based products.

5- By-products of Argan Oil are:

– Shells Argan oil production generates a lot of crushed shells; it is the most generated by-product. These shells have a high energy content that makes them an excellent biofuel. Well-known as they are traditionally used to make fire. Today, with some mechanical and enzyme pre-treatment, they have a promising future for bioethanol.

Due to the innovations in biomass (any organic matter that comes from plants) the shells found new appreciation and valuation; exported to a specialized stone fruit facility to be refined into a variety of bio powders. These powders contain enzymes, used to break down grease, dirt, and other proteins and are used in agriculture, cosmetics, and even road construction, to name a few.

Charred shells, ‘biochar’, improve the retaining of water and nutrients in the soil. Excellent for use in drought areas.

– Argan Press Cake As research and interest in sustainable practices continue to grow (300+ scholarly citations just in the first 6 months of 2023) Argan Shells and APC go beyond its traditional role as animal feed. Carbon and Polymers are studied as a pathway to adding environmental value to waste and by-products. Molecular docking ( a predictive tool) and Supercritical (anything 😊) are some en-vogue methods. A Japanese study, published in July 2021, showed APC extracts influenced stimulating hair growth and contributed to an anti-hair loss drug development. In January 2023, a study was published on a supercritical CO2 extraction of APC, resulting in a satisfactory kinetic extraction of edible oil.

– Argan Press Cake As research and interest in sustainable practices continue to grow (300+ scholarly citations just in the first 6 months of 2023) Argan Shells and APC go beyond its traditional role as animal feed. Carbon and Polymers are studied as a pathway to adding environmental value to waste and by-products. Molecular docking ( a predictive tool) and Supercritical (anything 😊) are some en-vogue methods. A Japanese study, published in July 2021, showed APC extracts influenced stimulating hair growth and contributed to an anti-hair loss drug development. In January 2023, a study was published on a supercritical CO2 extraction of APC, resulting in a satisfactory kinetic extraction of edible oil.

Leaves (and twigs) of the argan tree are used for stem cell extraction and studied for anti-aging properties. An October 2021 study profiles mineral elements and heavy metals in argan leaves and fruit by-products using spectrometry. Results: ‘rich in macro and micro-elements; lower levels of heavy metals demonstrating higher nutritional value and lack of toxicity concerns of Argan by-products‘.

Valuation of by-products and Argan’s Carbon Footprint

Are being studied, preliminary results, to the best of our knowledge, are in the ‘proof-of-concept’ phase.

A 2022 study by Reda El Boukhari et al.( Use of patent information to characterize innovation and trends in Food) is a good initiative to help valuation modeling.

Governmental regulations or a ‘best practices model’ of the real Carbon imprint within the Value (Supply) Chain of Argan oil is not established, according to some producers of Argan oil we asked. But hey, if we’re in the wrong, please let us know.

Read more:

Food Waste | The Nutrition Source | Harvard T.H. Chan School of Public Health

the-agriculture-transition-building-a-sustainable-future-v8.pdf

Argan Oil: Environmental and Ethical Concerns (treehugger.com)

This is everything you need to know about the Argan tree | World Economic Forum (weforum.org)

A World of Nutrition – IFT.org

International Congress on the Argan Tree | Agadir – Morocco (congresarganier.com)

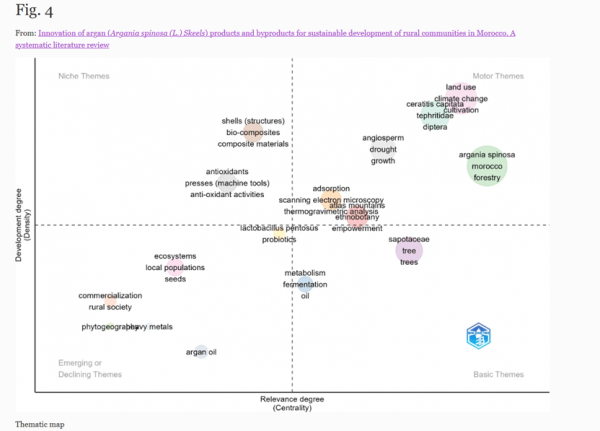

In desk research we found a ‘Thematic Map’, addressing (see fig. 4) the innovation of Argan and by-products for rural communities. The top left quadrant lists shells and antioxidants as niche themes.